- What is BIM |

- Why BIM |

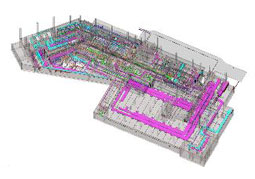

- 4D |

- 5D |

- 6D |

- BIM Benefits - ROI

- contact@steeltechengg.com

- 022 - 27580778 / 41230778

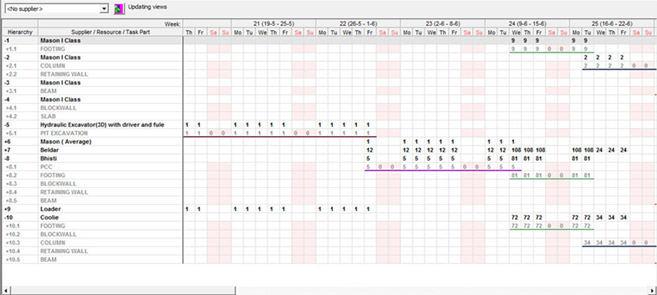

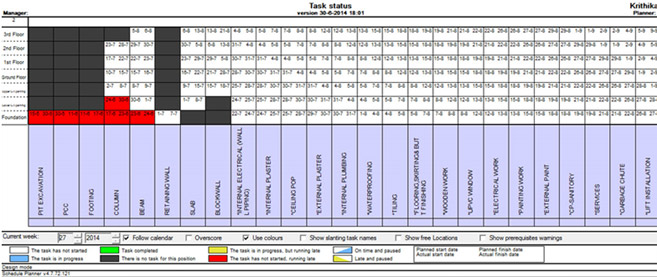

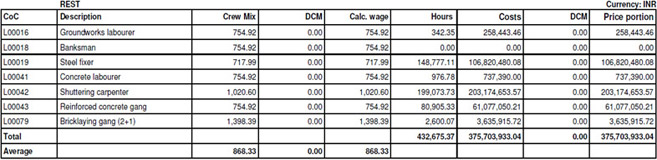

Location-based schedules are always resource-based because the intention is to optimize crew flow and improve project durations by targeting production rates. Resources are, in most cases, supplied by the subcontractors and not the entity which is responsible for project scheduling and production control. It has been our experience that black box approaches to production control do not work well. In order to maintain control, the GC needs to anticipate issues and proactively control production rates. And in order to do this, feedback from subcontractors is needed in real time.

In the planning phase after productivity data and quantities have been reviewed with subcontractors, a general commitment should be made to the overall shape of the initial planned resource graph. If the plan is good the overall shape should hold. However, everyone needs to recognize that the details will change. There is no correct productivity value – the productivity of individual workers is highly variable and even the same worker can have different productivity on a Monday and on a Friday. Therefore, it should be expected that adjustments will always happen. This can be done by reviewing the “current” forecast-based resource graphs regularly with the subcontractors.

Current resource graphs are based on actual productivity values for any tasks that have started and planned values for any upcoming new tasks. They also take into account any agreed control actions. By using the current resource graph, the GC can inform the subcontractors well in advance of additional resource requirements. Subcontractors should look ahead at least two weeks and inform the GC of any new planned mobilizations and demobilizations. If the forecast and subcontractors expectations do not align, either the forecast or expectations need to be changed. Typically the forecast would be adjusted first by using control actions and if the adjustment does not result in a detrimental outcome the subcontractor’s expectation can be accommodated.