- What is BIM |

- Why BIM |

- 4D |

- 5D |

- 6D |

- BIM Benefits-ROI

- contact@steeltechengg.com

- 022 - 27580778 / 41230778

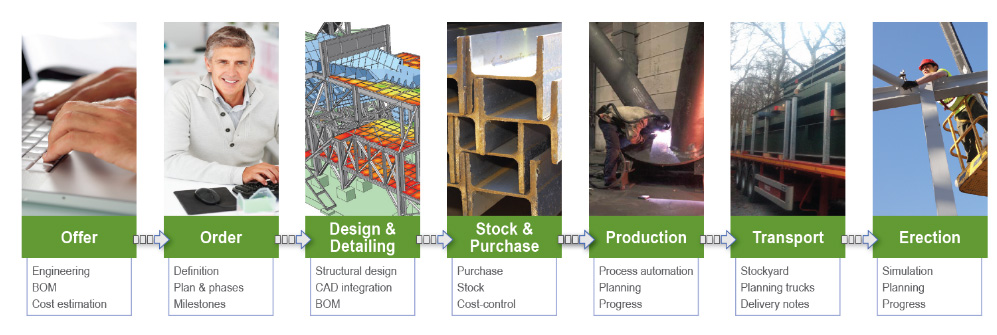

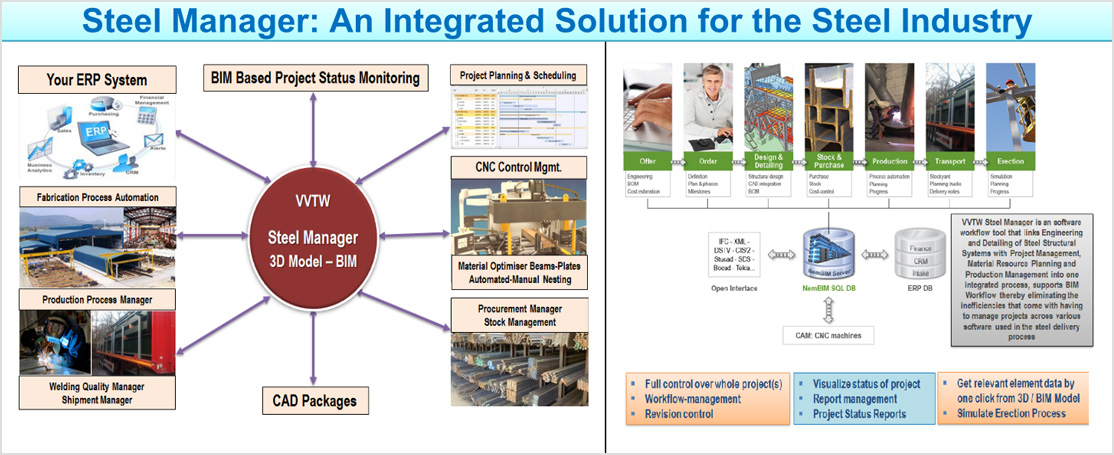

VVTW-Steel Manager is Structural & Coldform Steel Workflow Solution that links Engineering and Detailing of Steel Structural Systems with Project Management, Material Resource Planning and Production Management into one integrated process, supports BIM Workflow thereby eliminating the inefficiencies that come with having to manage projects across various software used in the steel delivery process. Steel Manager has got the ability to integrate with the detailing software like Tekla Structures, BoCAD, SDS/2 as well as AutoCAD while one can integrate drawings in PDF as well. In a single integrated modular solution

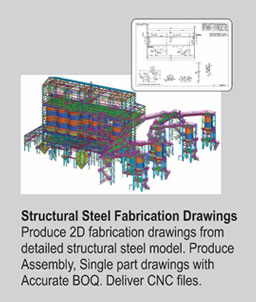

From the data issued by the drawings coming from any CAD system, the Steel Manager solution will be able to retrieve all the necessary information’s for the execution of any kind of steel structure project: residential, shopping malls, power plants, offshore platforms, transmission towers, PEB structure, tanks, bridges, stadiums. The Steel Manager system is able to manage the data for a complete automated fabrication process, setup along with the customer’s specificities (CNC machines, solutions used…) :

In a single integrated modular solution, it offers all of the following:

Steel Manager is modular with a view to increasing speed, quality and management efficiency of the

steel constructor. The nerve centre of the system is composed of the bill of material (B.O.M.) and the

geometrical data of this bill. The parameterization of Steel Manager guarantees that each organisation

feels perfectly at home within this IT-solution.

Furthermore, with its modular approach, customers have the advantage and the possibility to grow with

each change in the organisation of the company. Many steel constructors have already switched to CAD

and CNC-machines.

Steel Manager is the logical software link between CAD and CNC for the entire work preparation. In

short, Steel Manager is the pounding heart of your company, it receives information and passes

it on to related systems.

Amongst our clients we count both small companies with a few employees and large steel constructors

with over 1000 employees.

Key features of Steel Manager

Cost Savings Opportunities:

Time Savings Opportunities