- What is BIM |

- Why BIM |

- 4D |

- 5D |

- 6D |

- BIM Benefits-ROI

- contact@steeltechengg.com

- 022 - 27580778 / 41230778

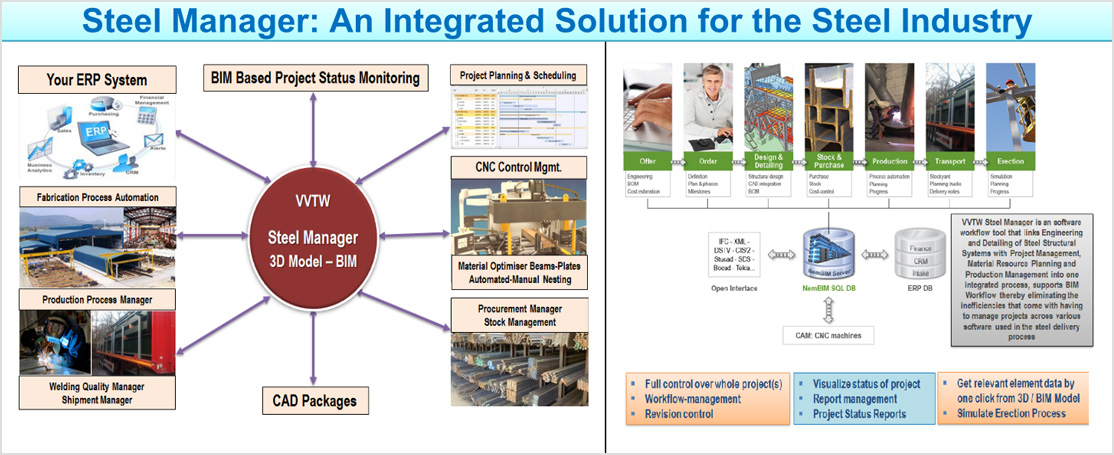

Ability to view the status of current projects and access project information’s, without having the opportunity to use them actively.

Project planning as a whole, linked to the company available resources. Gantt charts planning and project simulation (supply phase). Management of the resources giving a detailed view of all the resources and capacity linked with all ongoing projects

Routing to establish the automated production of each element through its various stages of production. Generation of production times estimations and reports along with progress monitoring.

Stock management including full traceability of materials (suppliers, orders ...) and managements of various stocks including off-cut management.

Purchasing Management generating purchases / orders suppliers, optimization of purchases (between different suppliers / subcontractors)

Automatic bar nesting management and optimizing cuts for the beams / bars.

Automatic plate nesting management and optimizing the plates cutting.

Personalized postprocessor for automatic steering of CNC machines

Managements of deliveries, shipment lists, trucks and lots

Welding and quality management with personalized database (welders, inspectors, subcontractors ...), and management of welding processes, certificates, inspections, reports and repair management.

Steel Manager Implementation is phase wise process and a customer specific project plan is developed initially studying all workflow, process, Machines and people involved in entire project execution. The implementation process is mainly targeted initially to address current bottleneck while all rest Steel Manager functionalities are implemented. Customization and some of part development becomes usual part of implementation. A due care I taken to develop custom manuals for usage by end user thus making permanent source for usage as and when required by any staff, senior or management team member.