- What is BIM |

- Why BIM |

- 4D |

- 5D |

- 6D |

- BIM Benefits-ROI

- contact@steeltechengg.com

- 022 - 27580778 / 41230778

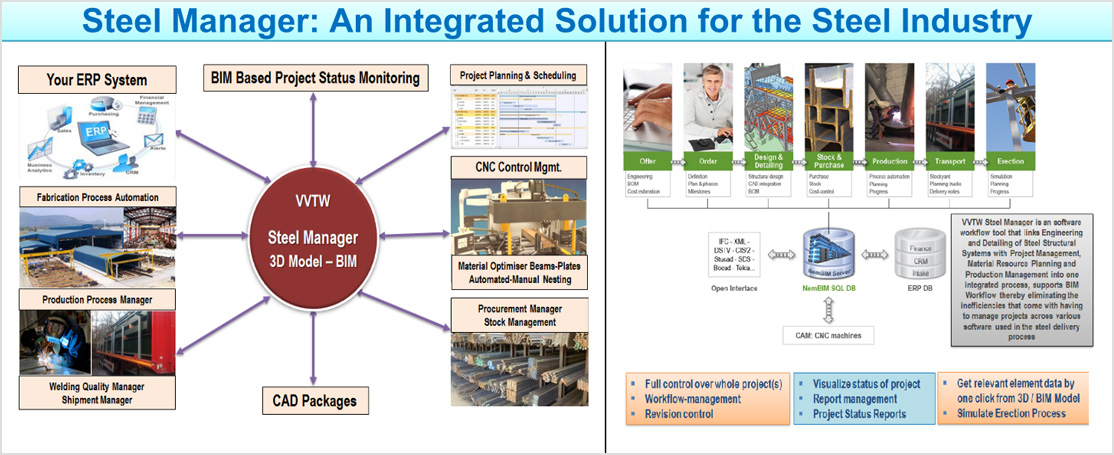

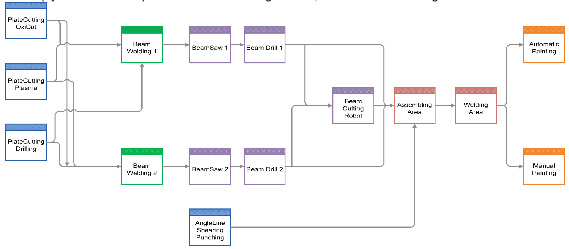

Within Steel Manager the entire production process is determined based on the following parameters:

Each position and assembly are linked to one or more what-parameters. Some typical what-parameters

are: saw cut, hole, outline, paint. They determine the geometry and the general characteristics of the

parts which have to be delivered. Mostly they are generated automatically in Steel Manager during

import from CAD-system using DSTV-NC files.

It is obvious that a hole, which has to be drilled, can be realized on several machines. The where-

parameter specifies clearly where each what-how- combination will be executed. This implies that a

position and/or assembly can go through different cost centers. In the extra parameter ‘production-

sequence’ the workflow is determined. For companies with various production locations, an extra

location parameter has been provided. In this way, specific parts can be planned and organized directly

from one location to the other.

At what time are these ‘what, how and where’ processed and at what time have they been executed

(planned versus realized). Production times can also be coupled to this when, in this way a planning as

well as a subsequent calculation are possible. The power of Steel Manager is the fact that due to a

simple parameterisation of your production process, the program automatically decides how and where

your production will be done; it starts directly after importing the CAD-data. When the production process

is specified, a detailed calculation method specified per cost center is used to determine the production

times. In a simple way the system registers what has been produced and in how much time. If the CNC-

machines allow it, this information is treated on-line.

This module gives you the possibility to follow up your projects in a graphical way. Using colors the

status of an assembly or element can be determined. Various filters allow to view particular parts and/or

statuses. A particular status can be the result of: – manual registration action – automatic registration

action (by external device) – semi – automatic registration, like barcode scanning

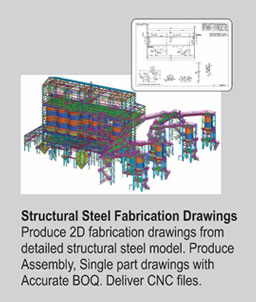

Work preparation for plates and beams

Within Steel Manager, CNC-machines are controlled Steel Manager data. This part is used in particular in the work preparation of the plate and profile machines. The following functionalities are available:

Reports via Crystal Report© or Microsoft Reporting Services ©