- What is BIM |

- Why BIM |

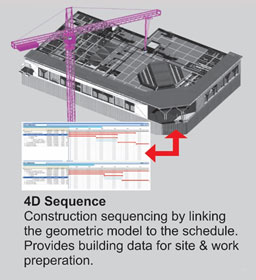

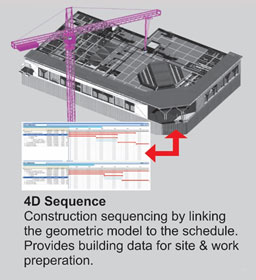

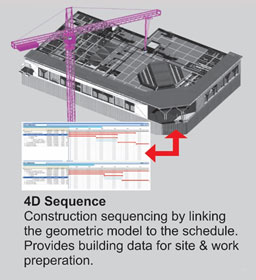

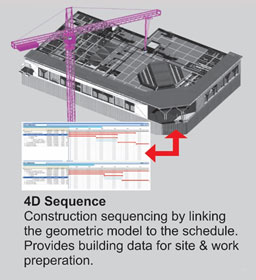

- 4D |

- 5D |

- 6D |

- BIM Benefits-ROI

- contact@steeltechengg.com

- 022 - 27580778 / 41230778

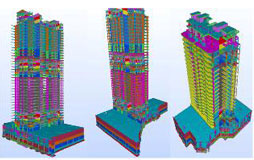

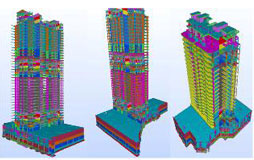

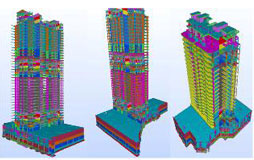

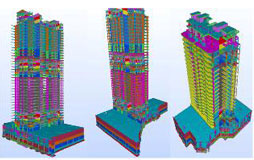

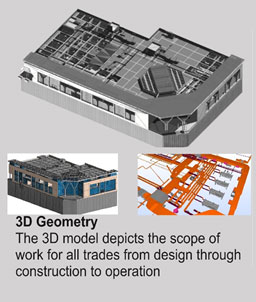

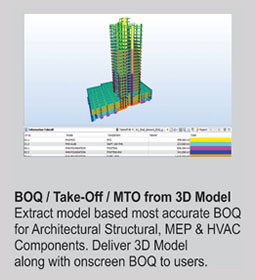

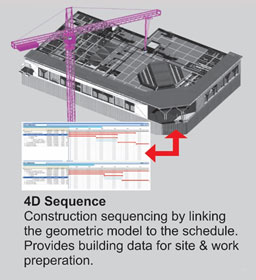

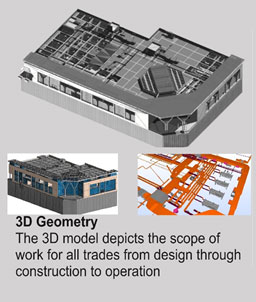

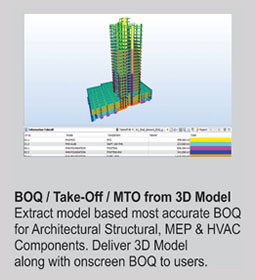

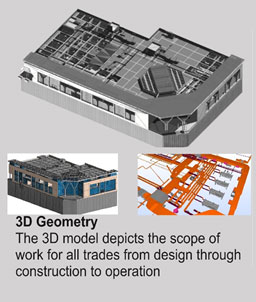

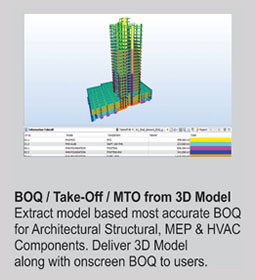

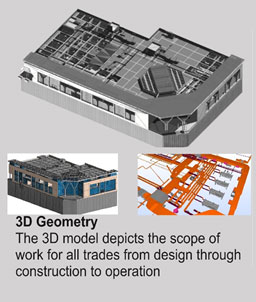

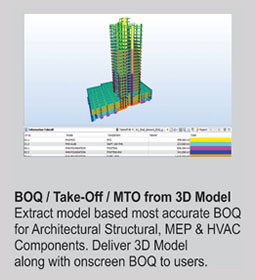

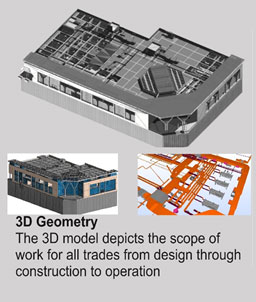

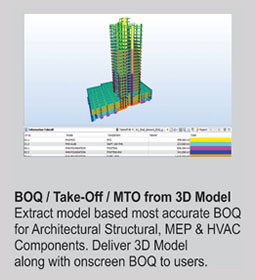

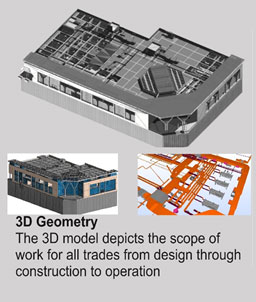

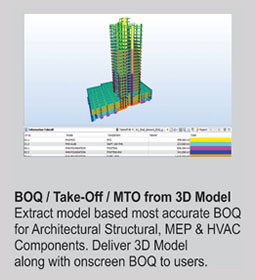

Building Information Modeling (BIM) generates a complete digital model of the building that can produce exact bill of material and cost estimate along with coordinated drawings and details. A conceptual building information model can provide a quick feedback on several design assumptions as the model contains components with historical cost data, productivity data and other estimating data. In BIM based estimating & takeoff system the design model is linked with estimating process and the quantity takeoff along with overall estimating process is greatly enhanced. The faster feedback on proposed design changes can be easily achieved.

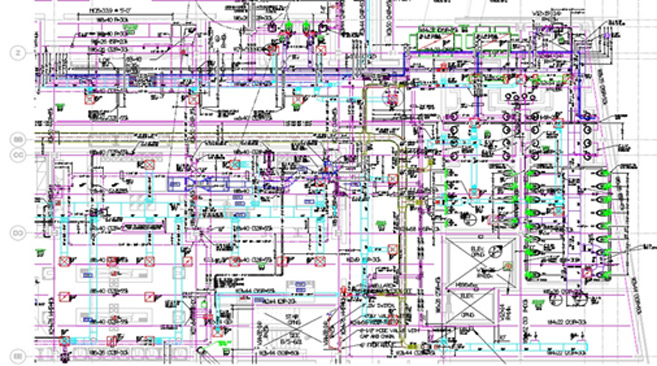

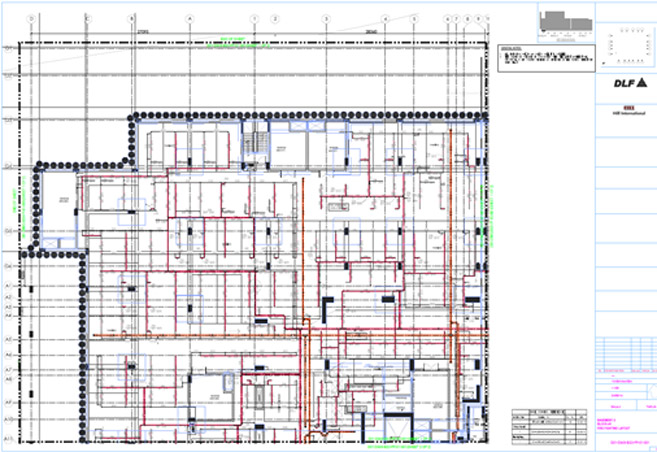

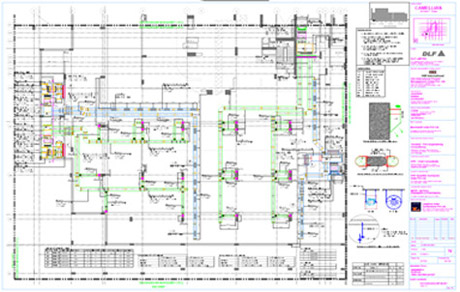

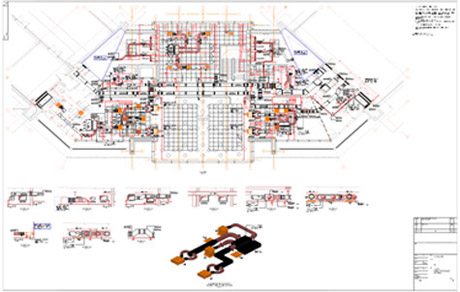

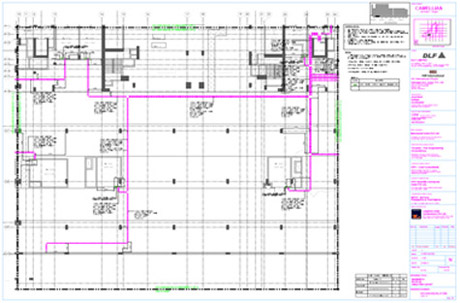

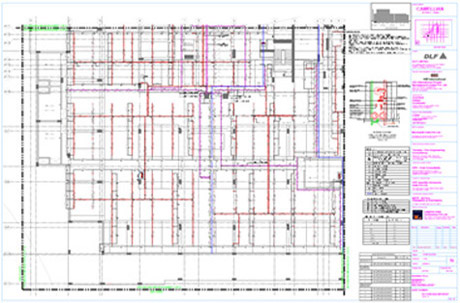

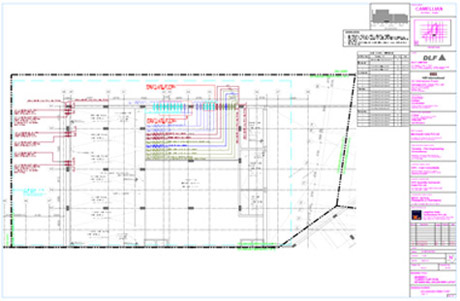

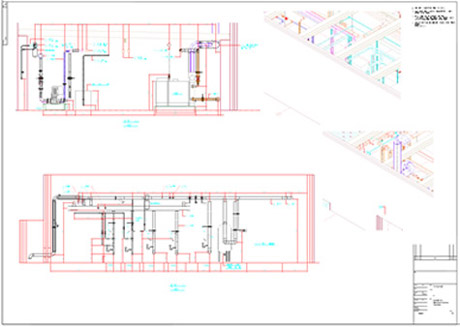

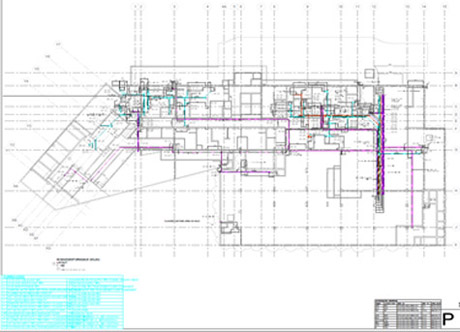

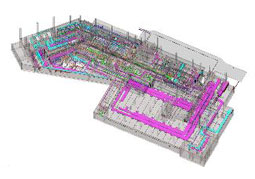

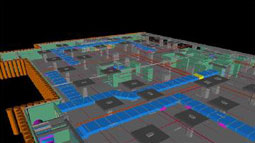

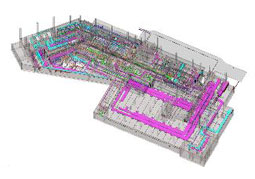

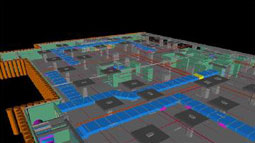

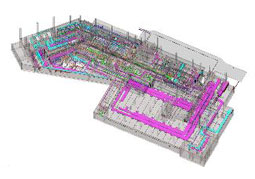

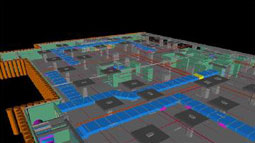

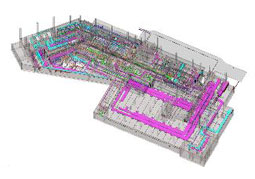

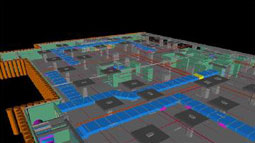

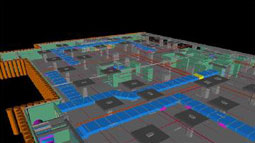

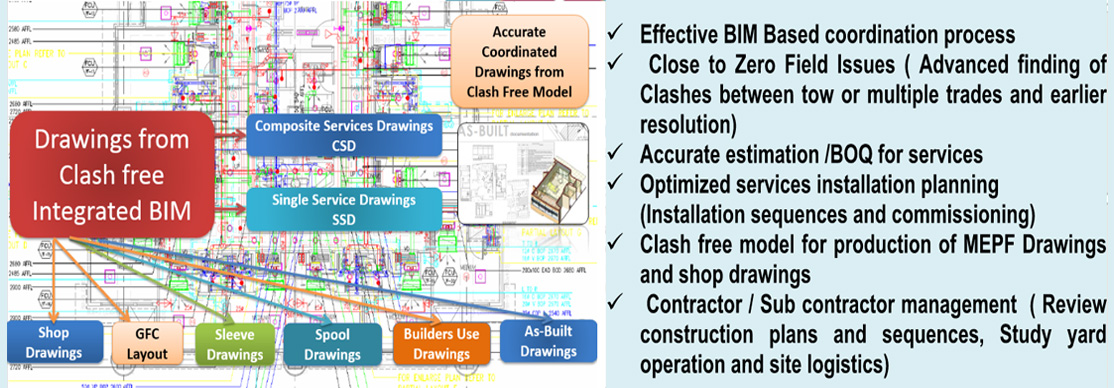

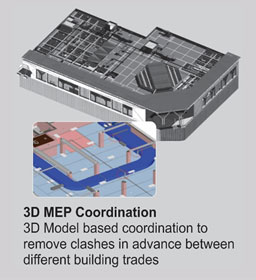

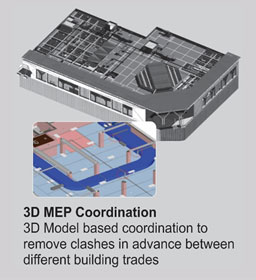

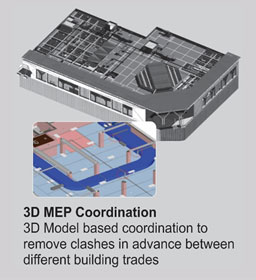

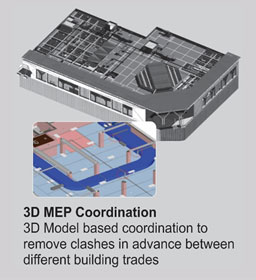

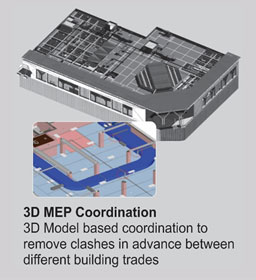

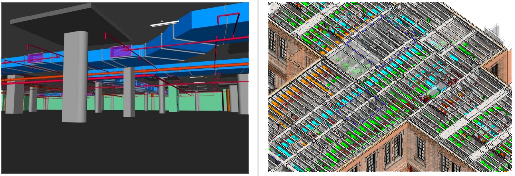

MEP 3D Model is effectively utilized for production for coordinated MEPF / M & E Drawings. These includes drawings at various stages such as,

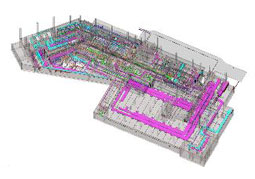

Once the clash detection & removal process is completed, SteelTech produces coordinated MEPF drawings from this clash free model. We are able to verify that our spatially coordinated MEP building services models work to engineering standards and constraints as well as the structural and architectural elements within a building.

Coordinated Service Drawings (CSD) is prepared by coordinating the MEP services like HVAC, Plumbing/Hydraulic, Fire Fighting and Electrical 3D Models with the Architectural, Structural, and Reflected Ceiling Plans (RCP). It is ensured that these services do not obstruct each other either physically or functionally. These are done as per the Clients requirements / Specifications, and strictly adhering to various International Standards.

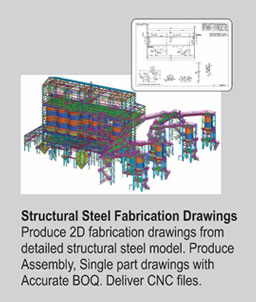

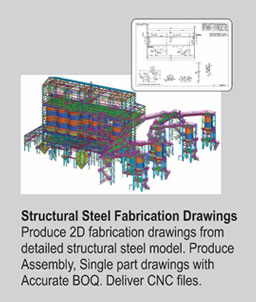

SteelTech has extensive experience on executing MEP 2D & 3D projects. Our team of engineers with manufacturing experience supports in converting your hand-drawn sketches, design concepts and drawings into 2D and 3D. We have developed CAD Toolbars to facilitate the production of drawings. We have executed number of projects for our customers in the areas of Oil & Gas, Chemical, Telecom and various Industry verticals. We do also generate Bill of Materials for assembly’s that ultimately, make it easy for our clients to plan inventory levels and production planning and help them achieve efficiency on the shop floor.

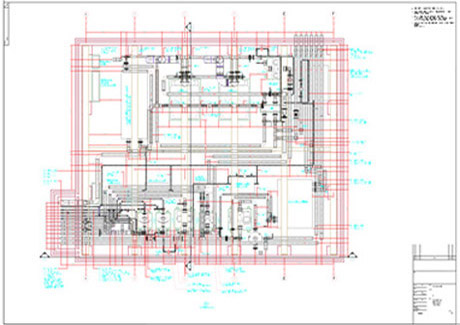

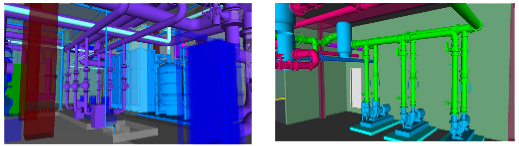

SteelTech will extend the power of BIM and improve mechanical prefabrication processes with Autodesk® Fabrication. Autodesk Fabrication helps mechanical, electrical and plumbing (MEP) contractors enhance their workflows by adding powerful design, detailing, and estimating and fabrication tools. Quickly move from a model into MEP fabrication or estimating with Autodesk® Fabrication. These impressive tools also allow you to use manufacturers’ specific information to help increase the speed and accuracy of your projects.

SteelTech will be using Autodesk® Fabrication suite. Fabrication CADmep software* supports detailing, fabrication, and installation workflows for mechanical, electrical, and plumbing (MEP) contractors. MEP fabrication videos demonstrate tools that extend design-intent to help you create more accurate, intelligent, constructible models of building services systems. The design model is transformed into detailing model before the

We ensure to have no collisions with the steel, ceiling and MEP elements. As an example, Fire Protection Shop Drawings : Fire protection piping. HVAC drawings showing installed ductwork with horizontal and vertical dimensions to avoid Fabrication & Spool Drawings : Sheet Metal Fabrication, Spool Drawings interference with structural framing, ceilings, partitions, equipment, lights, mechanical, fire Sleeve & Rough Drawings : Sleeves / Core Drill, Rough Openings protection, electrical and other services. The drawings provide top of duct and bottom of duct Additional Services : Sectional drawings and BOQ dimensions. These are extracted from clash free 3D Model. The necessary annotations, text and attributes are added so as to increase readability of drawings and more project and trade MEP Shop Drawing Services (Details Covered) information is made available. These drawings are utilized further by each trade contractor to HVAC Drawing Services install his equipment’s in space allocated for respective systems. Design drawings to shop drawings as per international

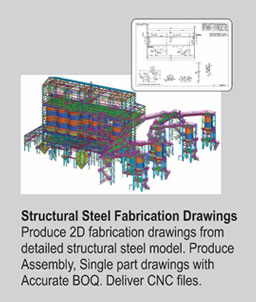

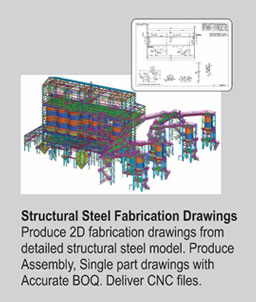

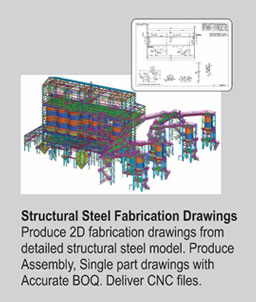

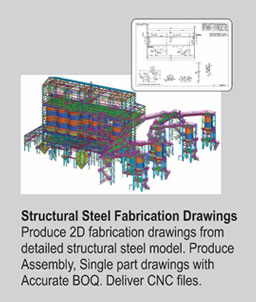

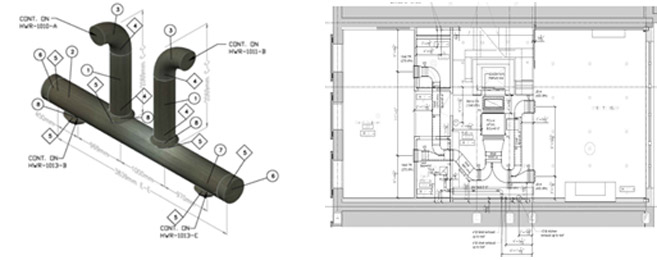

A shop drawing is a drawing or set of drawings produced by the contractor, supplier, manufacturer, subcontractor, or fabricator. Shop drawings are typically required for prefabricated components. Examples of these include: elevators, structural steel, trusses, pre-cast, windows, appliances, cabinets, air handling units, and millwork. Also critical are the installation and coordination shop drawings of the MEP trades such as sheet metal ductwork, piping, plumbing, fire protection, and electrical. HVAC Drawing Services install his equipment’s in space allocated for respective systems. Design drawings to shop drawings as per international

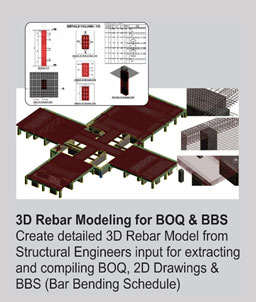

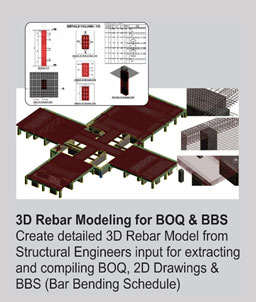

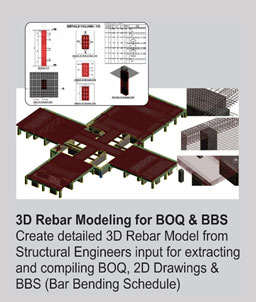

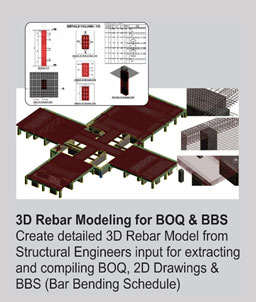

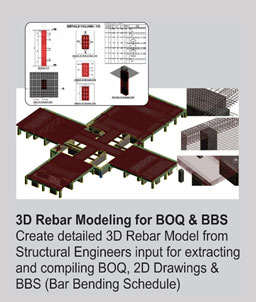

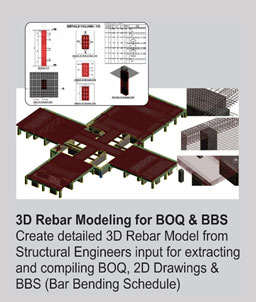

We can create 3D models from 2D drawings or adapt architects 3D models to allow for work breakdown structuring to an agreed SMM format. This can often be completed within the time constraints of tendering deadlines. SMM data (Standard Method of Measurement) generated for BOQ production enables BIM data to be used by sub-contractors for tendering as well as onsite teams for contract administration. The upfront effort is similar to a typical BOQ production, but the downstream savings in time and improved accuracy can be invaluable to project teams.

We can create 3D models from 2D drawings or adapt architects 3D models to allow for work breakdown structuring to an agreed SMM format. This can often be completed within the time constraints of tendering deadlines. SMM data (Standard Method of Measurement) generated for BOQ production enables BIM data to be used by sub-contractors for tendering as well as onsite teams for contract administration. The upfront effort is similar to a typical BOQ production, but the downstream savings in time and improved accuracy can be invaluable to project teams.

Designing a home to your custom needs is one of the goals of our Customer Service/Design Team. One design consideration is to incorporate a Central Core plumbing layout. Keeping your plumbing areas (kitchen / bathroom / laundry) near one another will save costs by reducing materials use, reduce water consumption, and improve the energy efficiency of the hot water heating system.

SteelTech will also be delivering Sleeve drawings, shaft drawings as well as spool drawings, which will be produced out of coordinated 3D BIM Model. The necessary dimensions, annotations and editing will be done so as to have highest level of clarity of drawings that can be used by installers/ sub-contractors onsite.

Our services are geared toward the fabrication side, leveraging all prior 3D design work by the Architect and Engineer OR BIM consultant in a manner that benefits the mechanical trade’s contractor. The finished product is an exact representation of the actual components allowing much of these systems to be pre-fabricated off-site where conditions allow maximum production and superior quality. We provide fast, friendly and professional services while maintaining the highest standards of quality